Application - AUTOMOTIVE

AUTOMOTIVE

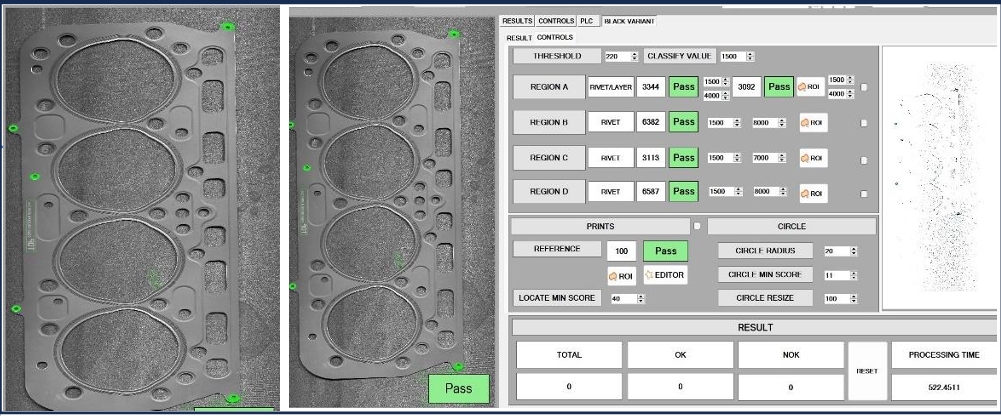

Project: Vision System for Gasket Element Monitoring

ASSEMBLY INSPECTION

A vision system is installed that automatically checks for the presence and correct placement of parts like rivets, layers, holes, prints, and notches, ensuring that each gasket meets standards and works properly. For example, it may detect the presence of a hole while confirming the absence of a rivet, and so forth for the other regions, allowing the vision system to even bypass inspection for elements not present in specific gasket variants, ensuring accurate and efficient inspection processes. the vision system ensures thorough and precise examination, contributing to the overall quality assurance of the gasket manufacturing process.

Technology Used

- 4K Line Scan Camera

- F- mount 75mm Lens

- Red Bar Light

- Aurora Vision Software

Highlights

- User-Friendly HMI

- Quick Recipe Selection

- Accuracy in Identification

- .Authentication Levels

AUTOMOTIVE

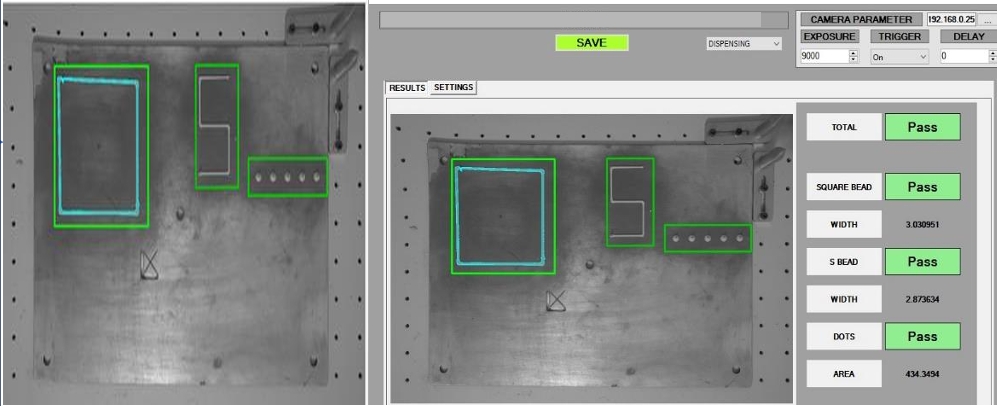

Project: Vision System for Dispensing Inspection

ROBOTIC GUIDANCE

In automotive manufacturing industry, a vision system in robotic dispensing enhances precision and adaptability by providing real-time visual feedback, allowing robots to recognize and accurately dispense materials in varied shapes and sizes. The camera captures detailed information about the object’s position and characteristics, allowing the system to extract accurate coordinates. The robotic dispenser uses this data to precisely dispense the required solution onto the square bead, an S bead and the dots. The OK/NOK condition is determined by assessing the width of the dispensed area.

Technology Used

- Basler 20MP Camera

- 8mm Lens

- Red Bar Light

- Aurora Vision Software

- White Square Light

Highlights

- Accuracy in Locating multiple objects.

- Excellent Repeatability

- Communication through PLC & LabView

- Authentication Levels

- Rapid Data Processing

AUTOMOTIVE

Project: Vision System for OCR & Depth Measurement

DEPTH INSPECTION

The Depth of Character (DOC) and OCR reading are essential to achieve high accuracy and precision in the production or manufacturing line. It enhances the overall performance and versatility in quality of products. The primary application was to detect OCR and depth of characters using 3D sensor. We have improved it by adding pattern matching in the program. From 3D scanner, the frame is acquired. Using Aurora Vision processing tools, we have scaled 3D data. With some pre-processing tools we get two types of data in the form of Surface & Image. Using scaled surface, we have calculated depth data and Image used for OCR.

Technology Used

- 3D Sensor

- Aurora Vision Deep Learning

Highlights

- .Accuracy in Depth Measurement & OCR.

- Quick Recipe Selection

- Automatic PDF Report Generation