Application - MANUFACTURING

MANUFACTURING

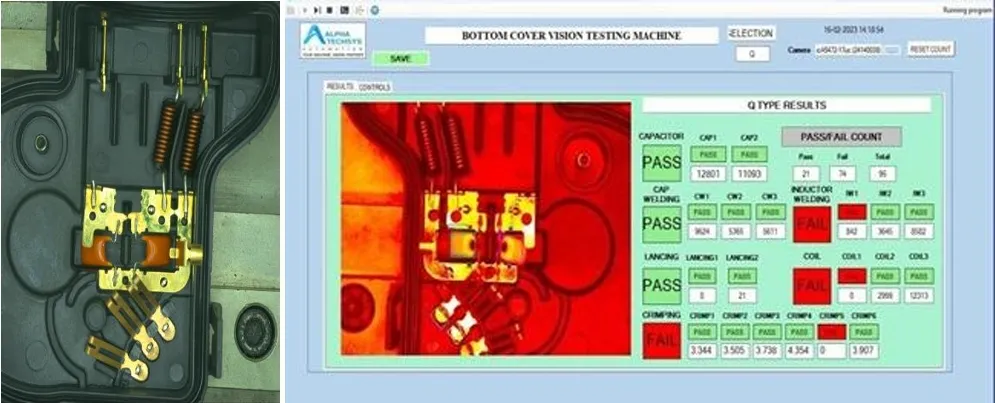

Project: Vision System for Terminal Box Inspection

PROCESS INSPECTION

Manufacturing industries requires optimized solution for their quality inspection of products. Vision inspection provides efficient solution with high accuracy which will increase the overall productivity and flexibility of manufacturing unit. We have successfully accomplished project as per the customer’s requirement. The requirement was to inspect child part presence/absence in terminal box and measurement of crimping part. We are able to get desired output on two variants.

Technology Used

- Basler 12MP Camera

- 25mm Lens

- Red Bar Light

- Aurora Vision Software

Highlights

- Single Camera to inspect all the parameters.

- Achieved accuracy up to 500 microns.

- Communication through Modbus TCP/IP.

MANUFACTURING

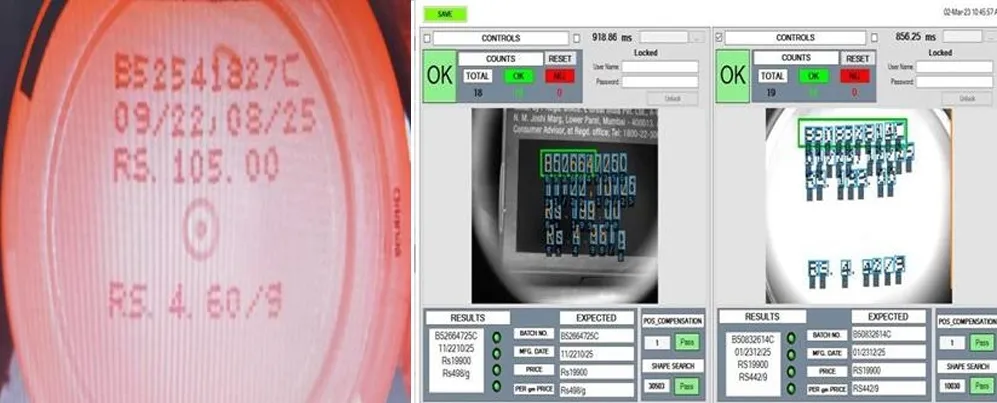

Project: Vision System for Label Inspection/OCV

LABEL INSPECTION

Consumer goods industries require vision systems for enhanced quality control and efficient production processes. These systems ensure accurate inspection, detection of defects, and verification of product placement, maintaining high standards and consistency across production lines. We have successfully implemented two systems of similar r equirement at customer’s production site. The requirement was to do the OCV and check print quality of the object. The challenging part was to get the accurate results in a very speed inspection. And in the bottle side there was bubble present we are able to read characters correctly in this situation as well.

Technology Used

- Basler 5MP Matrix Vision Camera

- 12mm Lens

- Red Ring Light

- Aurora Vision with Deep Learning

Highlights

- Parallel processing to inspect Carton Box as well as Container in Single application.

- Achieved processing time limit less than 400ms.

- Reading accuracy achieved more than 99% using Deep Learning OCR.

MANUFACTURING

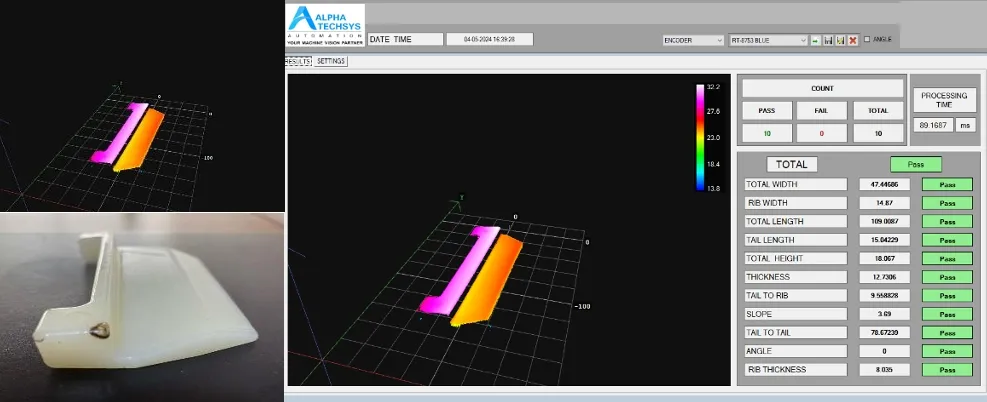

Project: Vision System for 3D Measurement

3D MEASUREMENT

We developed an advanced 3D measurement using AV software for a plastic manufacturer, greatly improving precision and quality assurance. The primary application was to measure various dimensions of an 3D object such as Rib Width, Total Width, Tail Length, Total Length, Slope, Angle etc. The profiler, equipped with cameras and sensors, collects detailed surface information. The AV software processes these images and data to generate a point cloud and create a detailed 3D model. Advanced algorithms are then applied to measure various dimensions of the object, such as rib width, total width, tail length, total length, slope, and angles, ensuring high precision and accuracy in the measurement.

Technology Used

- 3D Profiler

- Aurora Vision Software

Highlights

- Accuracy in 3D Measurement up to 200 microns

- Automatic PDF report generation

- Quick Recipe selection