Application - Special Purpose Machine (SPM)

Special Purpose Machine (SPM)

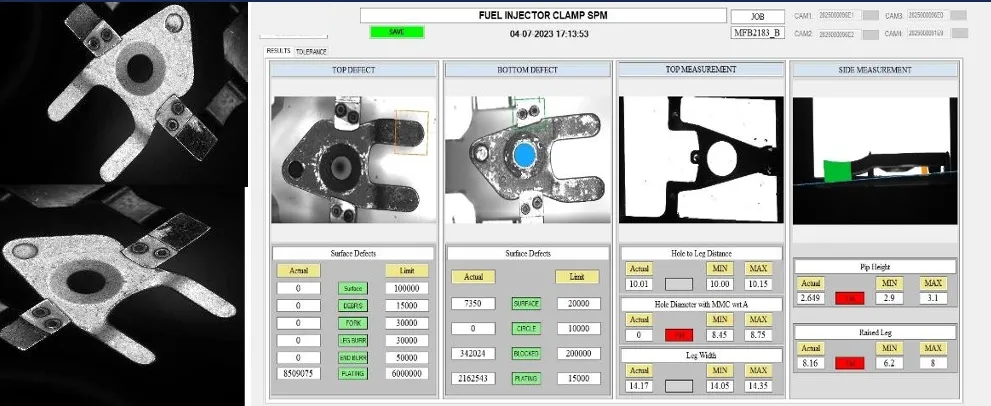

Project: Vision System for Defect Detection & Clamp Measurement

QUALITY CONTROL

SPM Industries require solutions to check qualities of the components of their machines. The project consists of 4 camera setup to detect defects and measurement for top, bottom and side view of component by Aurora vision software. In this, we have used traditional image processing tools such as blob, edge detection for measurement. Additionally, used Deep Learning tools for defect detection. First two cameras used to capture TOP & BOTTOM image for defect detection. Third one is for measurement from TOP side and the last one for SIDE view measurement. For parallel processing of all these 4 cameras, we have used multi-thread licensing in Aurora Vision Software.

Technology Used

- Basler 20MP & 5MP Camera

- White Ring Light & White Back Light

- 35mm & 50mm Lens

- Telecentric lens

- Aurora Vision with Deep Learning

Highlights

- Parallel Image Processing

- Achieved accuracy near about 50 microns

- Use of Telecentric lens for better accuracy in measurement.

Special Purpose Machine (SPM)

Project: Vision System for T-Putty micro-component Inspection

DISPENSING INSPECTION

Dispensing of T-putty on 5G-router base used as coolant for PCB. In absence of such coolant resulting overheating and may cause short circuit. There will be multiples points of dispensing T-putty in very large FOV, so it is difficult to inspect each and every position manually by an operator. In order to check the quality and accuracy of the process we have provided vision-based solution. Based on different variants selection, operator can easily change the parameters of the tools. These settings will be saved as a config file for respective recipes, later user can access the same setting on that particular variant.

Technology Used

- 20MP Basler Camera

- 16mm Lens

- Balluff lights

- Aurora Vision Software

Highlights

- Detection of small T-putty size in large FOV.

- Single HMI exe can work for all 18 different variants.

- Communication done through TCP/IP.

- Recipe selection done via PLC.

Special Purpose Machine (SPM)

Project: Vision System for Intensity Inspection of Electronic Console

INTENSITY INSPECTION

Electronic Devices such as Voltage regulators, Speedometer, 7-segment display needs continuous monitoring for proper functioning to avoid false data displaying. With the help of Vision system, we can monitor these devices 24*7 and inspect the quality of LEDs. We have implemented this solution to check the intensity of LEDs. In case of device malfunctioning, intensity of the LEDs starts fluctuating. We inspect the fluctuations based on the threshold values and we provide Ok and NOK signal to the PLC through Modbus/TCP. To get accurate results, we have created enclosed mechanical setup with no external illumination into encloser.

Technology Used

- 20MP Basler Camera.

- 25mm Lens.

- Aurora Vision Software

Highlights

- Single Camera system to detect all the parameters.

- User friendly HMI

- Communication done with Modbus TCP/IP.